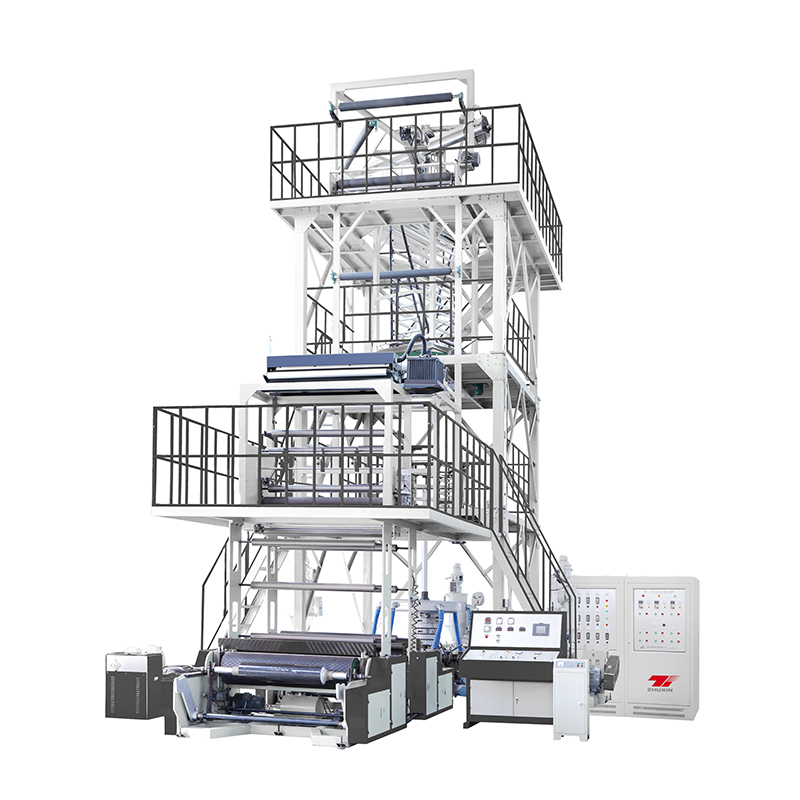

Three-layer co-extrusion internal bubble cooling haul-off rotary film product line:

Applicable for the materials as LDPE, HDPE, LLDPE, etc. It is widely used to manufacture composite film basic material, liquid film, contractive film, protective film, cable film, macromolecule adhesive film, multi-functional industrial film products, can better meet operational requirements of high accuracy and high speed color printing, composite and painting products.

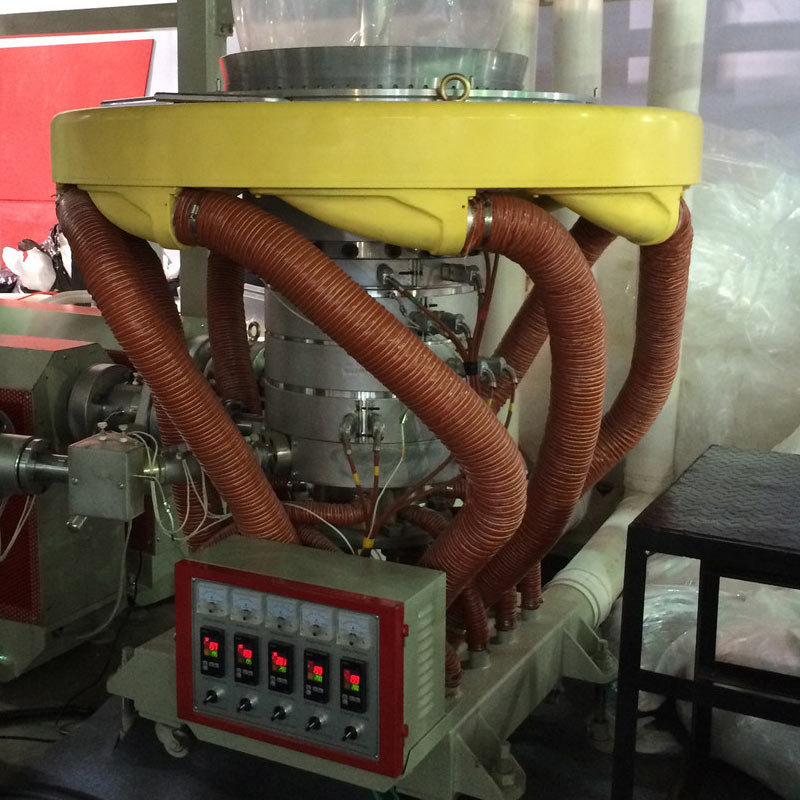

IBC system: As introduced by foreign advanced technology, this system adopts ultrasonic sensors to pass the signal to computer. By adjusting the speed of air blower that exchanges cool and hot air in the bubble, so as to ensure the size of bubble fold diameter.

product video

product video

Inquiry Now

Inquiry Now