Plastic bag making machine efficiency depends on four core elements: quality raw materials for product durability, consistent maintenance to minimize downtime, skilled operation for optimal settings, and advanced automation with real-time monitoring. These factors collectively ensure reliable production and industry compliance, highlighting the machine's essential role in modern packaging solutions.

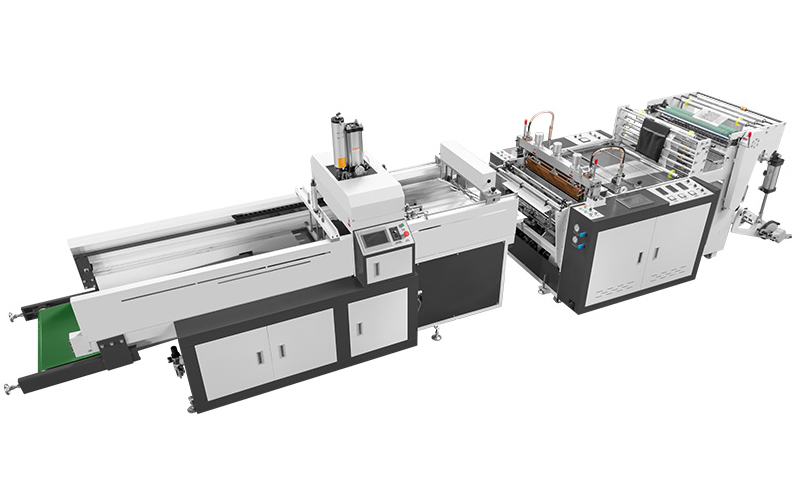

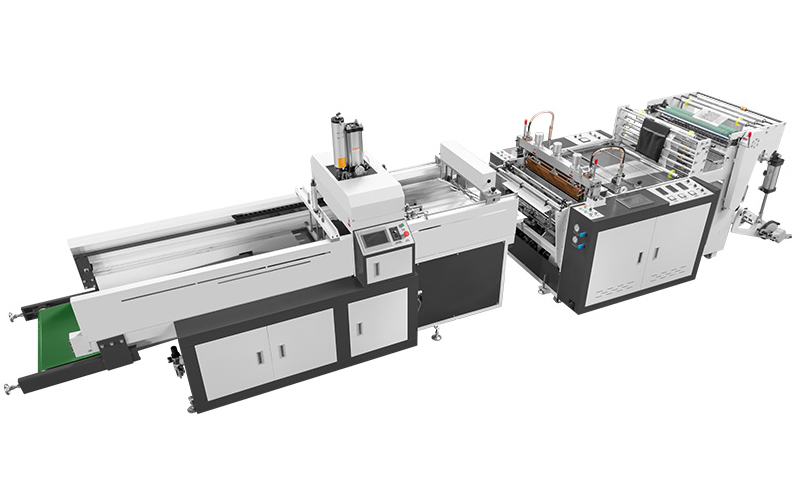

Understanding the Anatomy of Plastic Bag Making Machines

Plastic bag making machines are intricate devices combining various components to create bags efficiently. Understanding these machines begins with their core structure, which typically includes a film unwinding unit, a sealing section, and a bag formation zone. The film unwinding unit feeds plastic resin in roll form into the machine, where it undergoes pre-heating. In the sealing section, heated elements fuse the sides of the film, leading to bag formation.

A table below highlights key components and their functions:

|

Component

|

Function

|

|

Film Unwinding Unit

|

Dispenses raw plastic film for processing

|

|

Heating Section

|

Provides thermal energy for sealing

|

|

Bag Forming Zone

|

Shapes and cuts the sealed film into individual bags

|

The role of each component is crucial; any malfunction can hinder production efficiency. Moreover, advancements in materials and technology continuously improve the performance of these machines. Understanding this anatomy enables manufacturers to optimize their operations and adapt to changing market demands in the packaging industry.

The Role of Material Preparation in Bag Manufacturing

Material preparation is a critical first step in the plastic bag manufacturing process. It involves selecting the right type of plastic resin, which serves as the raw material for production. This resin undergoes a series of processes, including drying and blending with additives to enhance properties such as durability and flexibility.

Properly prepared materials ensure that the bags produced meet industry standards for quality and performance. The efficiency of material preparation directly impacts the speed and yield of bag formation, making it essential to optimize this stage.

Additionally, advancements in technology allow processors to better control material characteristics, leading to improved consistency in production operations. As manufacturers focus on these preparatory steps, they contribute significantly to overall productivity within the packaging industry.

Exploring the Process of Bag Formation in Plastic Production

The bag formation stage is crucial in the plastic production process, where raw materials are transformed into functional bags.

Initially, polyethylene or other plastics are extruded into a film via a die. This film is then cooled and wound onto rolls for easy handling. Next, the rolls are fed into the bag-making machine, where they undergo several processes, including cutting, sealing, and forming.

During cutting, precise measurements ensure that consistent bag sizes are achieved. Sealing techniques such as heat sealing or ultrasonic sealing join the edges effectively, ensuring durability.

Additionally, folding mechanisms may be employed to create designs like side seals or bottom gussets, enhancing functionality for various packaging needs.

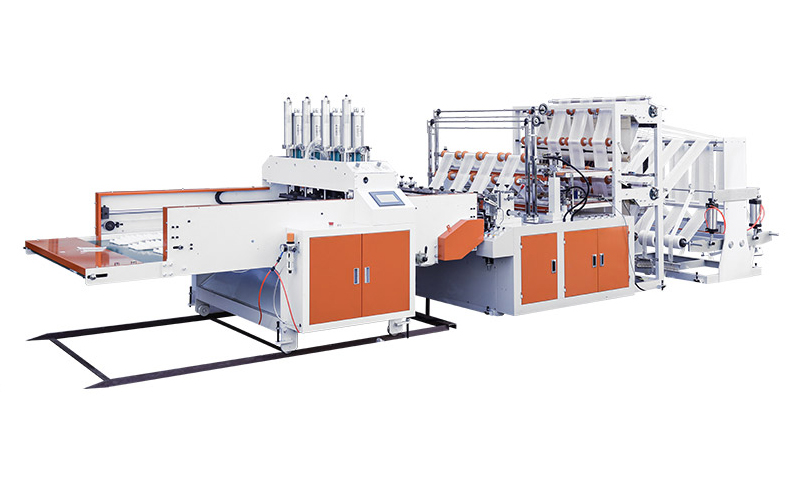

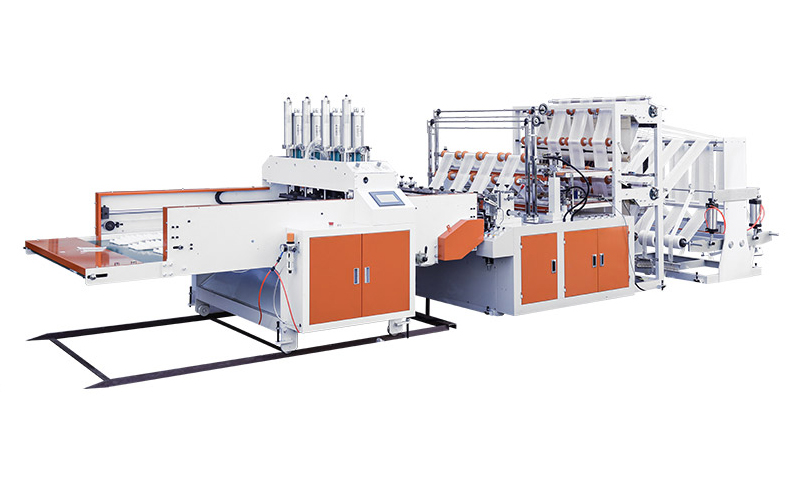

Innovations in Technology for Plastic Bag Making Machines

Recent advancements in technology have significantly enhanced the performance and efficiency of plastic bag making machines. Automation plays a crucial role, allowing for precise control of the manufacturing process, which reduces waste and optimizes material usage.Advanced sensors and smart software systems enable real-time monitoring of production parameters, ensuring consistent quality in bag formation.

Additionally, innovations in heating and sealing technologies have improved the durability of bags while speeding up the overall production cycle. These advancements not only streamline operations but also adapt to varying material types, allowing manufacturers to meet diverse market demands effectively.

Improving Production Efficiency in the Packaging Industry

Enhancing production efficiency in the packaging sector involves optimizing various stages of the plastic bag manufacturing process.

- Rapid Material Preparation: Enables quick loading of pre-cut films and raw materials.

- Automated Operation: Reduces manual intervention and accelerates production cycles.

- Thickness Control: Maintains consistent material quality to minimize waste.

- Flexible Production: Allows fast switching between bag types to meet diverse demands.

By streamlining these processes, manufacturers not only reduce costs but also respond better to market demands, ultimately driving profitability in a competitive landscape.

Key Factors Influencing the Performance of Plastic Bag Machines

The performance of plastic bag making machines hinges on several critical factors:

- Material Quality: High-grade polymers ensure bag durability and flexibility.

- Component Precision: Accurate cutting and sealing mechanisms guarantee dimensional consistency.

- Preventive Maintenance: Regular servicing minimizes downtime and sustains efficiency.

- Operator Skill: Trained personnel optimize settings and resolve operational issues.

- Advanced Technology: Automation and real-time monitoring enhance production consistency.

Advancements That Enhance Packaging Solutions with Plastic Bags

Recent advancements in plastic bag making technology have significantly improved the efficiency and versatility of packaging solutions.Enhanced automation features now streamline the production process, reducing manual intervention and minimizing errors.

- These machines are increasingly equipped with smart technology, allowing for real-time monitoring and data analytics, which further boosts productivity.

- Innovations in materials have led to the development of eco-friendly plastic alternatives that maintain durability while catering to sustainability concerns.

- These machines can be adapted for various bag designs, enhancing their applicability across different sectors within the packaging industry.

As a result, manufacturers can better meet diverse consumer demands while optimizing operational effectiveness.

Conclusion

As manufacturers adapt to evolving market demands, staying informed about trends and advancements reinforces their positions in this competitive landscape, ultimately benefiting both the industry and consumers.

Act now!

Contact our customer service team for free shopping guides and the latest product catalogs!