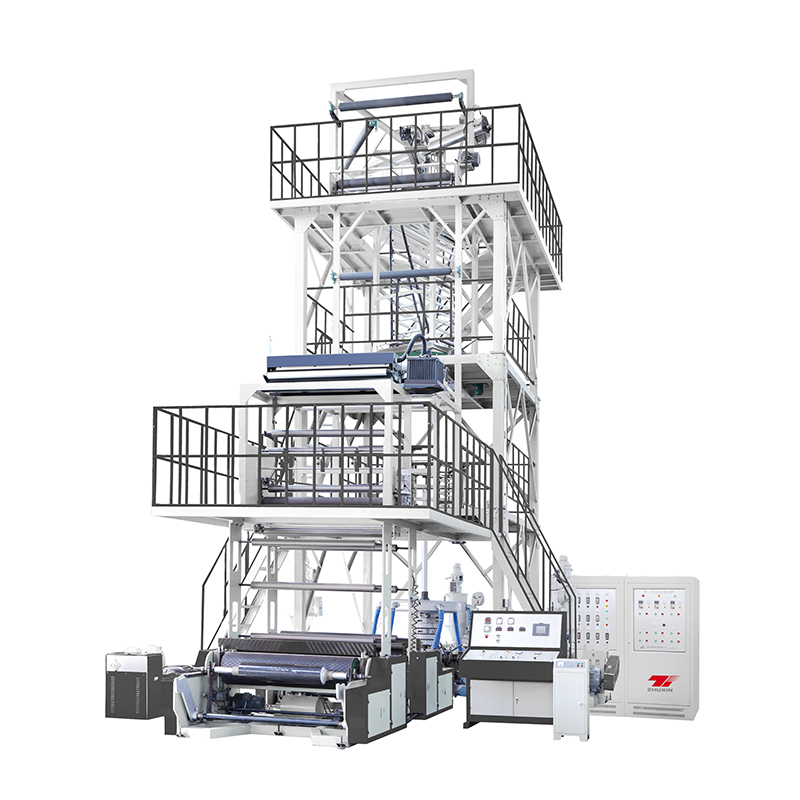

3SJ-G Series Three Layer Co-extrusion Rotary Die Head Film Blowing Machine Set

3SJ-G series three layer co-extrusion rotary die head film blowing machine set is designed and developed by our company based on market demand. It is optimum designed on the trounds of preference of analogous lines in foreign and home. This line can continuously blow 800/1500mm folding width 0.08mm thick packaging film, which has good insulation properties such as insulation, moisture resistance, antifreeze, rain resistance, frost resistance, insulation, oxygen resistance, oil resistance, etc. It is used for light and heavy packaging, such as fresh fruits, meat feed, salted vegetables, fresh milk, beverages, etc.

product video

product video

Inquiry Now

Inquiry Now