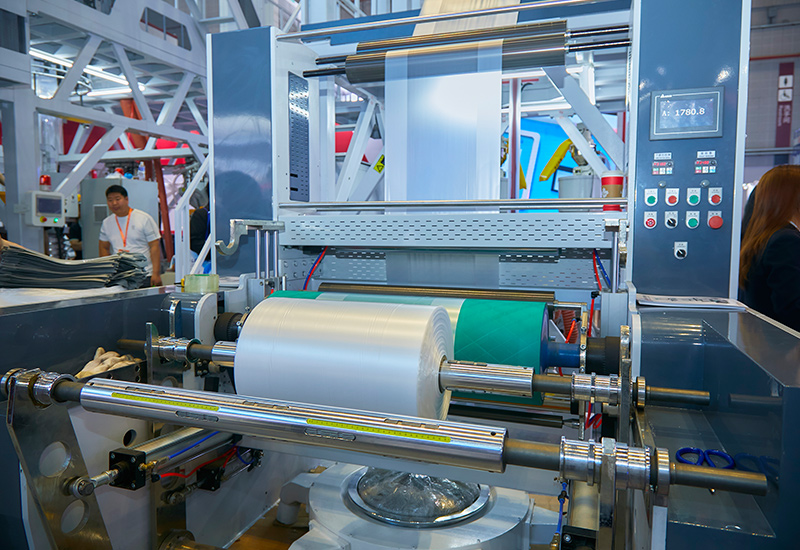

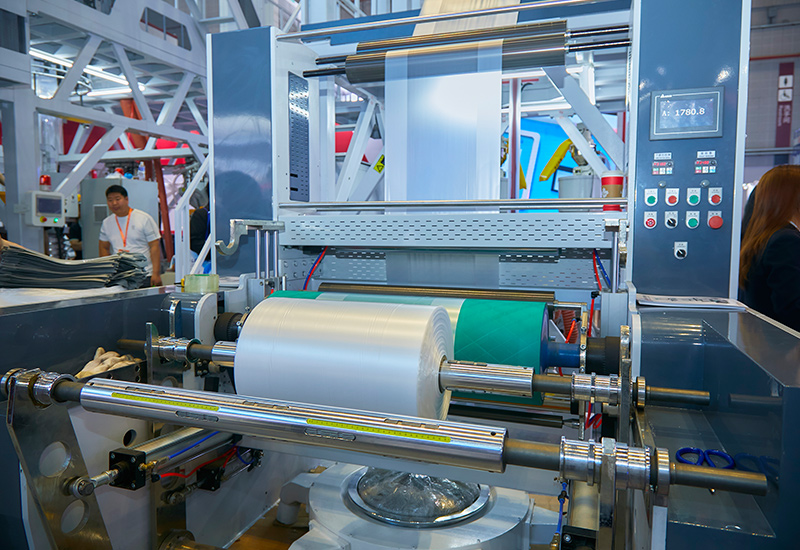

Running a blown film machine seems straightforward but small daily errors cause major quality and downtime issues. We’ve seen these problems repeatedly across hundreds of factories. Most are simple to prevent with the right approach.

- Rushing startup is a top mistake. Turning on heaters and feeding material too quickly leads to uneven melting and unstable bubble formation. Always let the machine reach stable temperature before starting production. This prevents unnecessary wear and ensures consistent film quality.

- Ignoring air ring maintenance causes wrinkles and thickness problems. Clogged air rings or incorrect settings disrupt cooling airflow. Clean the air ring regularly and adjust the gap based on your film width. Proper airflow is essential for smooth production.

- Skipping daily lubrication for rollers and bearings is another common error. Without regular greasing, parts seize up, create noise, and damage film. Include this in your daily checklist—it takes minutes but avoids costly breakdowns.

- Using the same settings for all materials is a frequent oversight. LDPE, LLDPE, HDPE and biodegradable resins need different temperature and speed profiles. Track settings for each material type to maintain quality. Your machine adapts but requires proper input.

If you’re facing film quality issues or need help optimizing your setup, we’re ready to share practical advice.

Email inquiry@zhuxinmachine.com or message us on WhatsApp at +86-13968935808.

Tell us what you’re producing and what’s going wrong. We’ll give you clear, experience-based solutions.