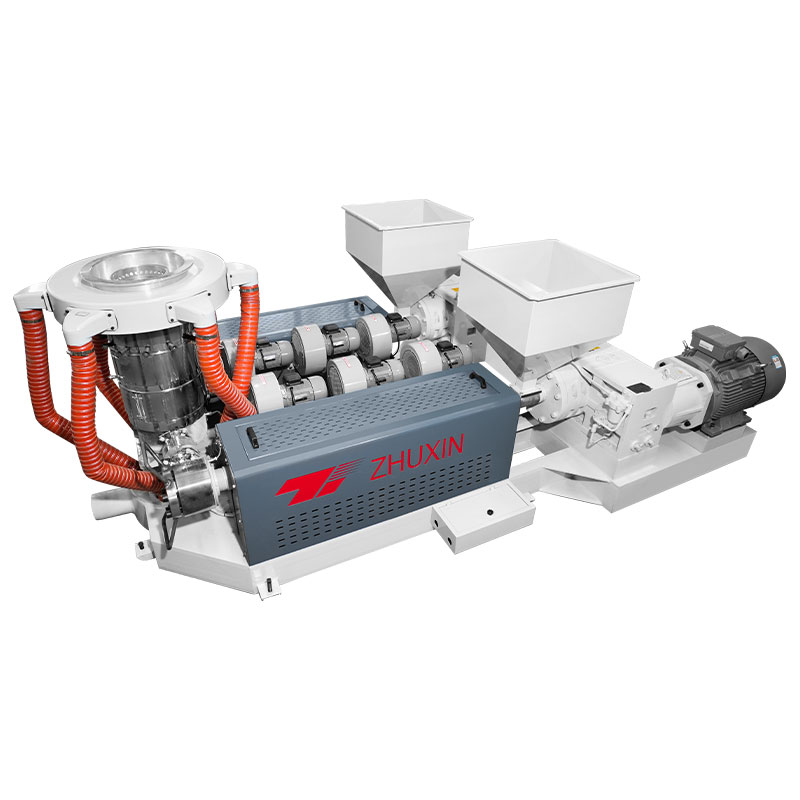

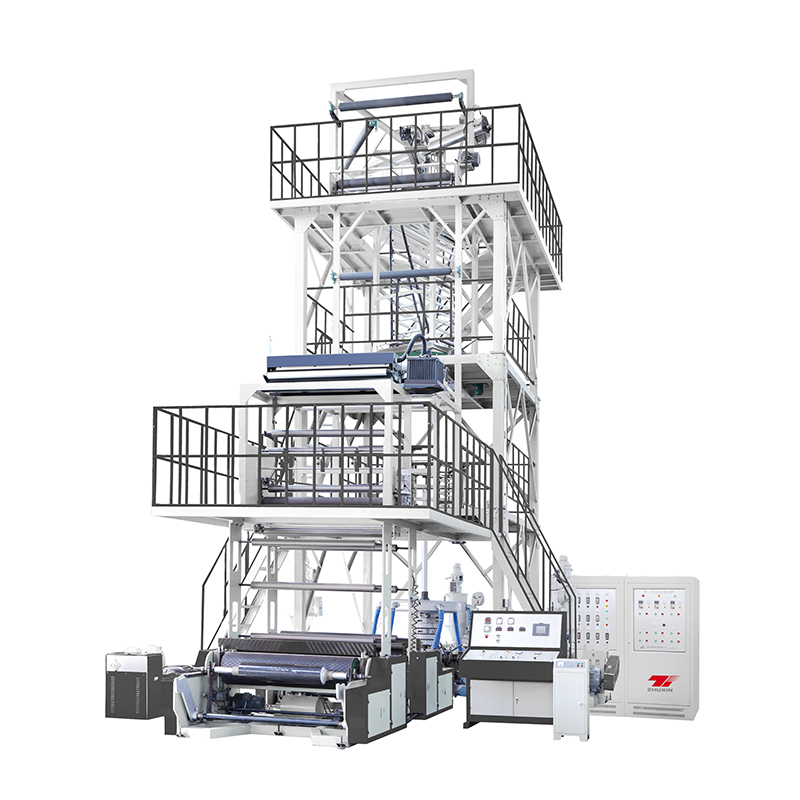

Three layer co extrusion technology

ABA film blowing machine uses two screws to extrude the surface and bottom materials respectively, and the middle layer is provided by another extruder, forming a three-layer structure of A, B, and A. This structure not only reduces raw material costs, but also improves the strength and physical properties of the film.

Material Applicability

Suitable for HDPE, LDPE, LLDPE and other materials, and can even be blown into biodegradable materials to meet environmental protection requirements.

Equipment durability

The main components such as screws and barrels are made of high hardness alloy steel, which is corrosion-resistant and durable; Die head plated with hard chromium to ensure uniform extrusion of materials and high film smoothness.

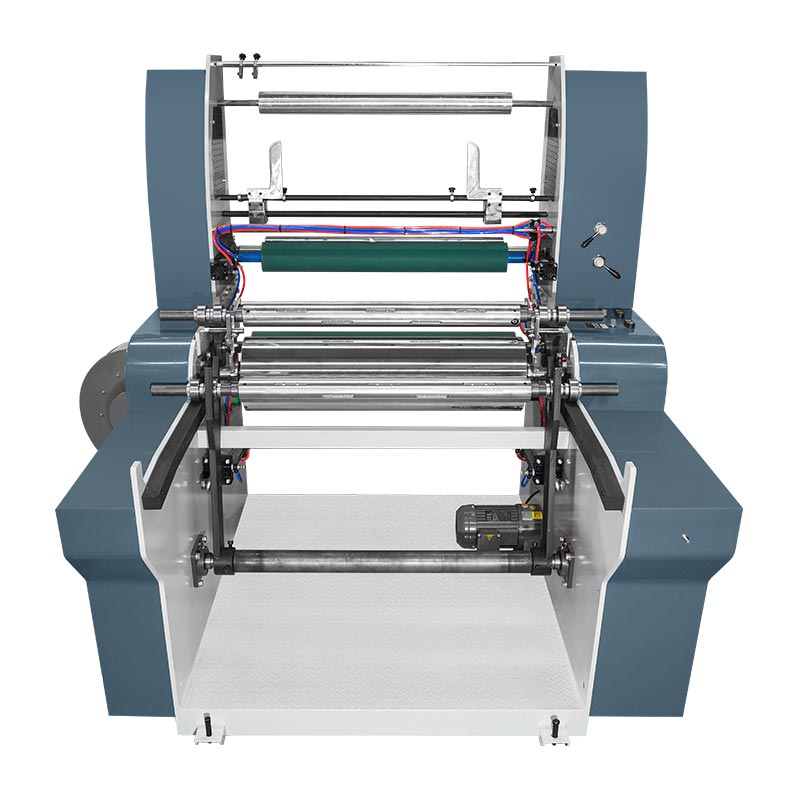

Production efficiency and quality control

Advanced control systems are adopted to ensure the stability of the production process and the uniformity of film quality.

product video

product video

Inquiry Now

Inquiry Now

.jpg)