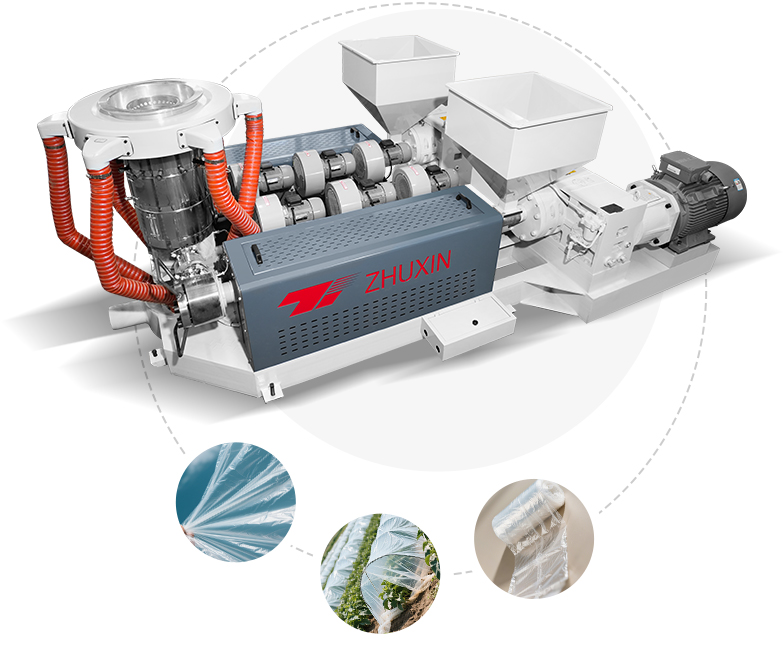

The blown film machines are known for their precision process, energy saving, environmental protection and intelligent control, and are widely used in high-precision film manufacturing fields such as food packaging, agricultural mulch, industrial protection and medical materials.

Energy saving and high efficiency

Accuracy control

Modular expansion

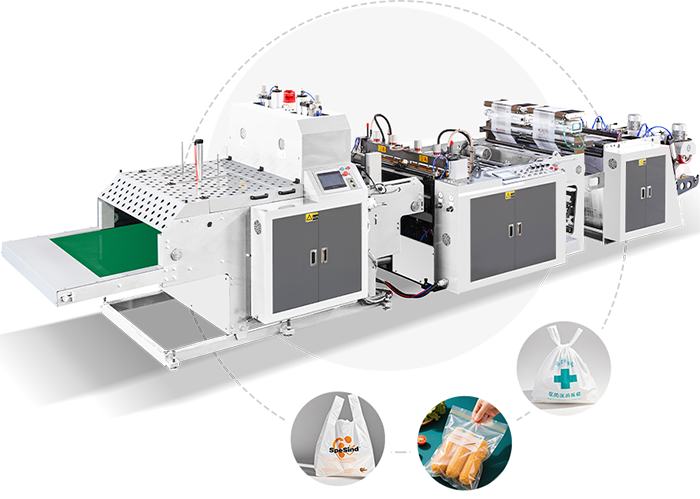

Multi-functional integrated bag making equipment, supporting the production of vest bags, three-dimensional bags, zip bags and other bag types, integrated visual inspection and scrap rejection, the yield rate of up to 99.5%.

High-speed and stable

Flexible adaptation

Intelligent quality control

Intelligent equipment focusing on the production of biodegradable paper bags, suitable for kraft paper, lamination paper and other materials, supporting the process of carrying handles pasting, die-cutting and creasing, and conforming to the FSC environmental protection certification standard.

Environmentally compatible

Efficient output

Low loss

Full servo-driven gravure printing machine with AI overprint correction system, suitable for BOPP, PE, aluminium foil and other materials, maximum printing speed up to 450m/min, support 10-colour high-precision pattern printing.

Overprint precision

Green production

Fast order change

Covering automatic feeding system, film bubble internal cooling device (IBC), slitting and winding machine and other ancillary equipment, to achieve intelligent control of the whole process of blown film production line.

Seamless docking

Energy saving and consumption reduction

Remote operation and maintenance