In today’s plastic film manufacturing industry, performance and efficiency go hand in hand. One technology that's reshaping the way films are produced is the multilayer coextrusion blown film machine. If you're involved in packaging, agriculture, or industrial film production, you’ve likely heard the term. But what exactly is it, and why does it make such a difference?

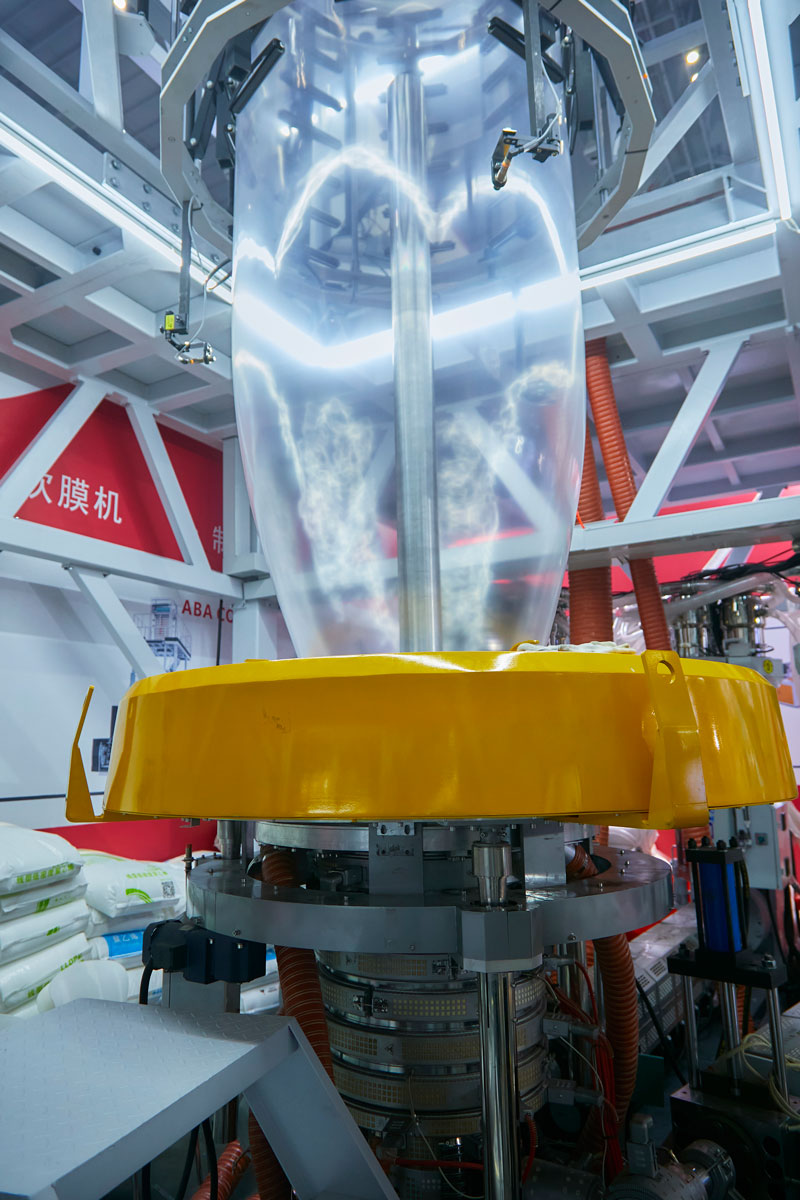

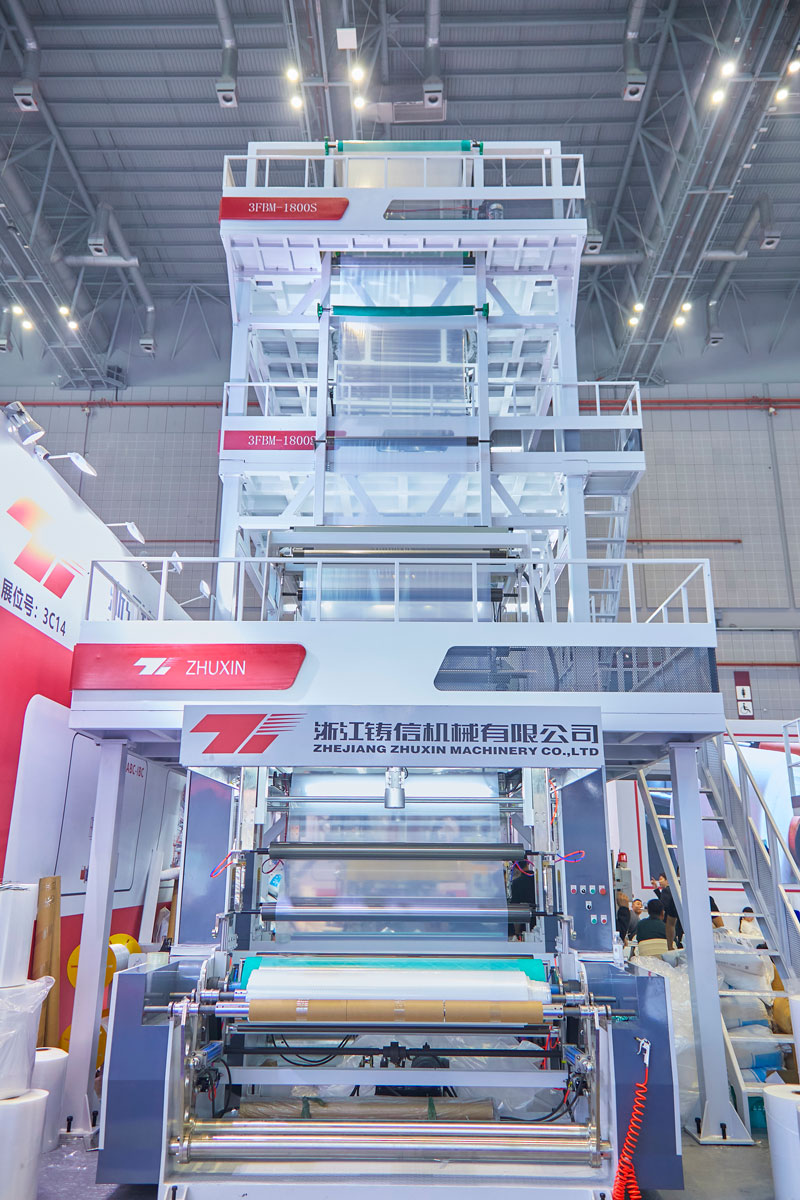

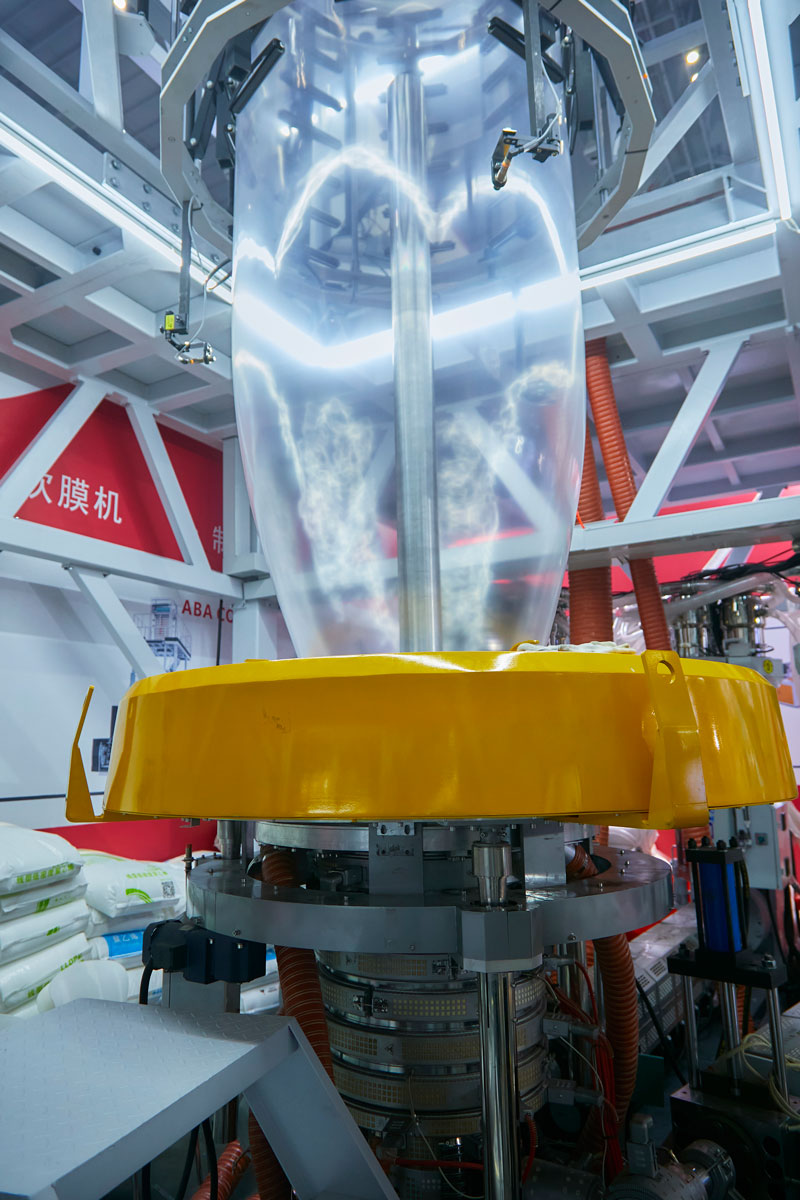

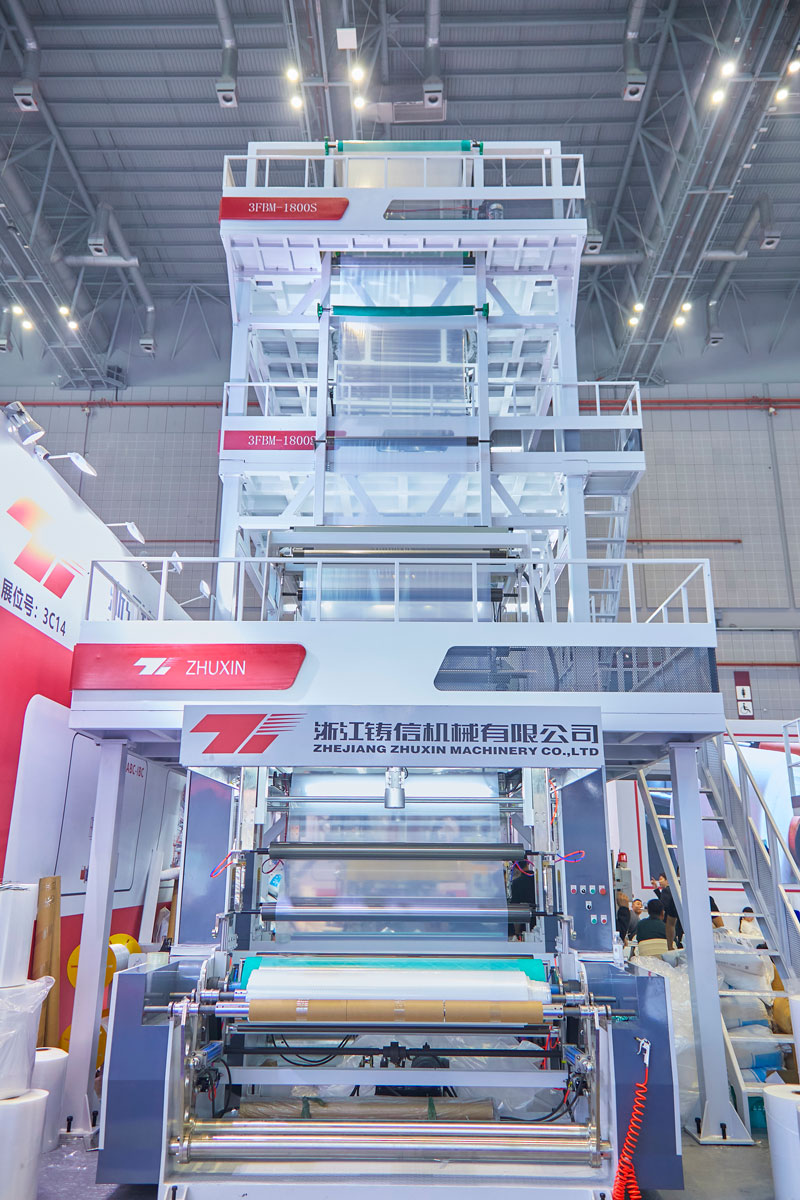

A multilayer coextrusion blown film machine produces plastic film by combining two or more different polymer materials into a single film structure during the extrusion process. Instead of relying on just one type of resin, this system uses multiple extruders to feed different materials—like HDPE, LDPE, PP, or specialty barrier resins—into a single die where they are fused together into layers. The result is a composite film that leverages the best properties of each material.

For example, a three layer film might have a tough outer layer for durability, a middle layer made of EVOH or PA for blocking oxygen and moisture, and an inner layer designed for strong heat sealing. Five layer configurations offer even greater control, allowing manufacturers to fine tune performance for demanding applications.

One of the biggest advantages of this technology is performance optimization. You get a film that’s stronger, more resistant to environmental factors, and better suited for sensitive contents like food or medical products. At the same time, it’s cost effective. Since high performance materials are only used where needed, you save on expensive resins while still achieving superior results.

Another major benefit is material efficiency. By precisely controlling each layer’s thickness, producers can reduce overall film gauge without sacrificing strength or barrier properties. This not only cuts raw material costs but also supports sustainability goals by using less plastic. Many modern coextrusion lines also include energy saving features like internal bubble cooling (IBC), automatic thickness control, and variable frequency drives, further improving operational efficiency.

Multilayer machines are also highly adaptable. Whether you're making shrink film, heavy duty sacks, agricultural covers, or sterile medical pouches, the ability to customize layer structure means you can meet specific customer requirements with ease. The films come out with excellent clarity, consistent thickness, and minimal defects, which translates to less waste and higher yields.

As market demands shift toward smarter, lighter, and more sustainable packaging, multilayer coextrusion has become a go to solution for forward thinking manufacturers. It’s not just about making film—it’s about making better film, faster and with less waste.

At Zhuxin, we design and build advanced multilayer blown film lines that combine precision engineering with real world reliability. From three layer to five layer systems, our machines are built to help producers stay competitive in a fast moving industry. If you're looking to improve film quality, expand your product range, or reduce production costs, multilayer coextrusion could be the right step forward.