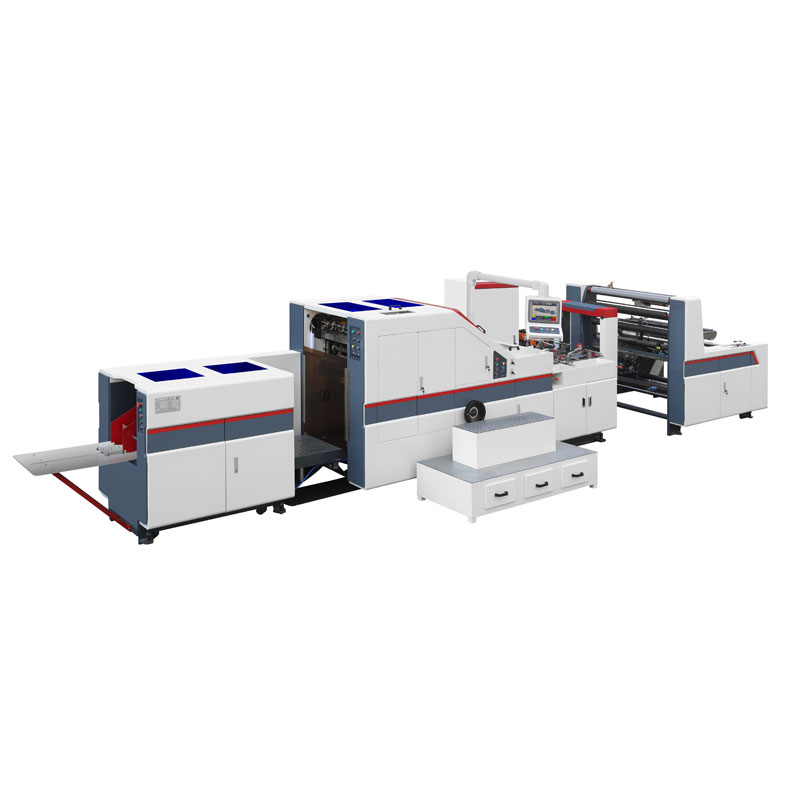

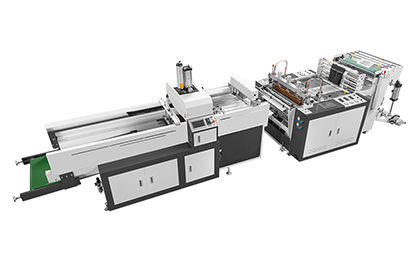

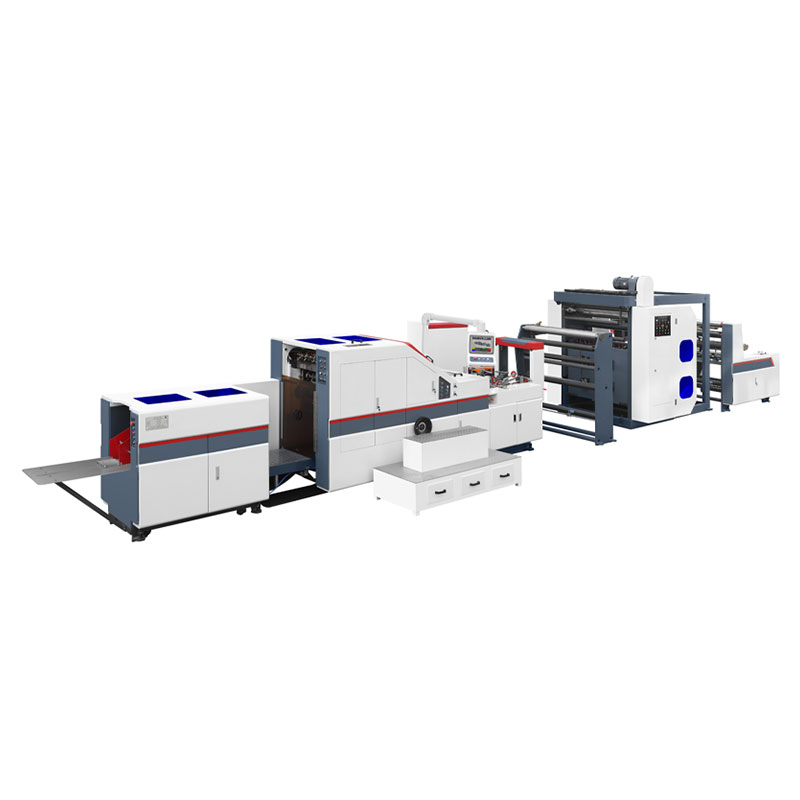

ZXFD-180/290/330/460 Square Bottom Paper Bag Making Machine With Printing Machine Inline:

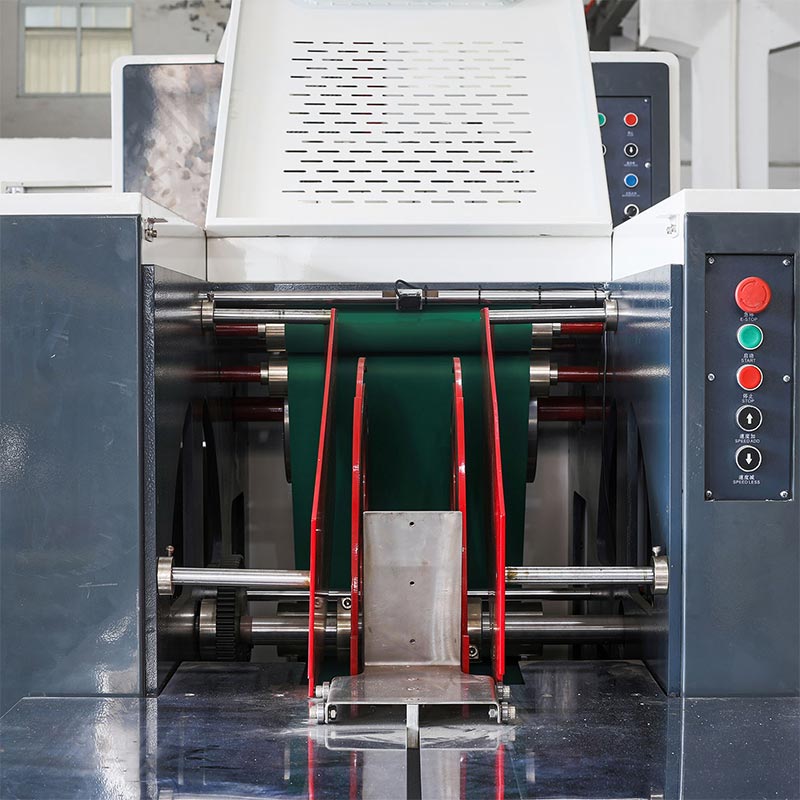

Full automatic high speed square bottom paper bag making machine is suitable for varied primary and printed rolling paper, such as kraft paper, slick paper, coated paper, medico paper and so on. It finishes all procession all in a time consisting: perforating, middle gluing, printed pattern calibration, tube forming, calibration snapping, bottom folding, bottom forming, and collect final product quantitatively. This machine operate easier, working more efficient, and performance more steadily. It is a fantastic machine for full paper bag, paper bag with window, leisure snack bag, bakery bag, fast food bag, dry fruit bag eco-bag and so on.

Bag-making width:220-460mm

Bag-making length:260-533mm

Bag-making speed:180pcs/min

Inquiry Now

Inquiry Now