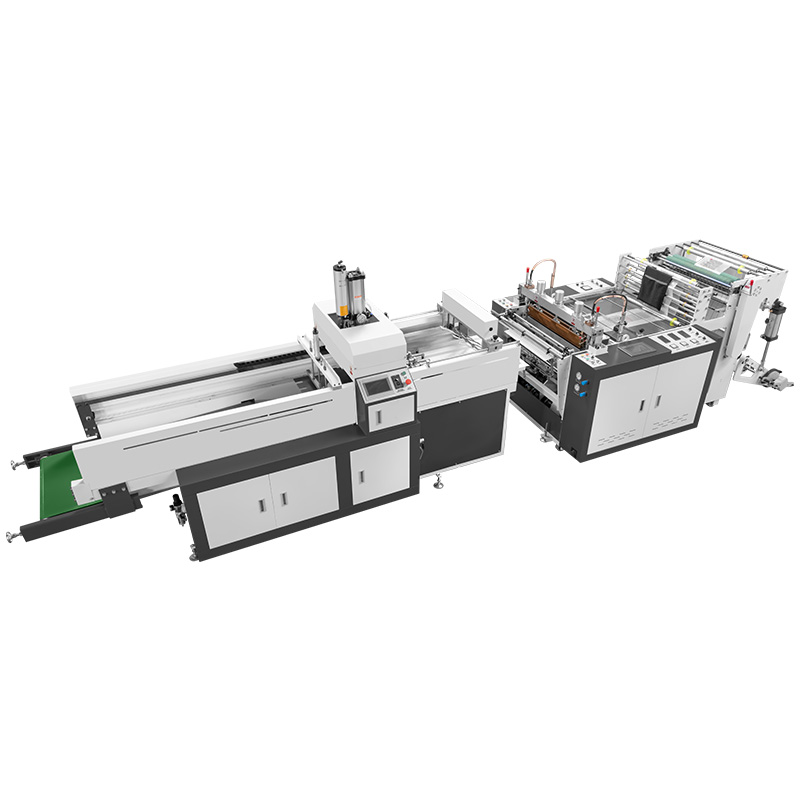

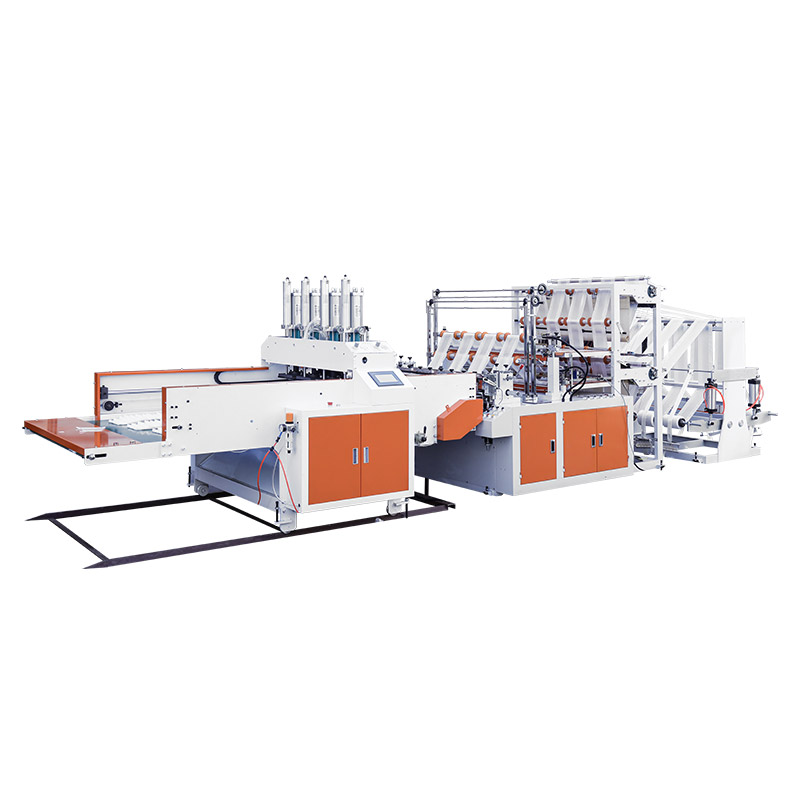

1. This machine can produce natural color and printed vest bags using HDPE, LDPE, LLDPE and other materials as raw materials. Using a computer programming control system and servo motor automatic length setting, the entire process of feeding, sealing, cutting, punching, and conveying is completed in one go.

2. Configure servo motor control systems with computer control and PLC LCD screen display, combined with photoelectric eye tracking control, for more efficient operation, smooth bag making, and accurate sealing and cutting.

3. The design of automatic feeding system, automatic punching machine folding device, and conveyor belt bag feeding function makes the operation more convenient and the bag making process more stable.

4. Swing type discharge system, combined with bag bottom shaping design, ensures neat bag collection and accurate punching position.

5. The cutting blade adopts current independent heating, high-precision temperature controller for automatic temperature control, easy operation, and accurate temperature control.

product video

product video

Inquiry Now

Inquiry Now