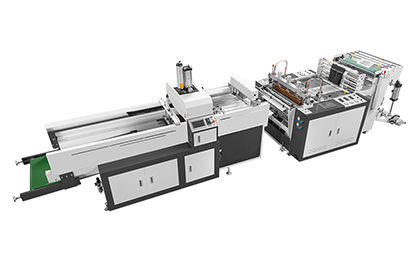

Full process computer control

USing PLC control, easy to operate, high degree of automation.

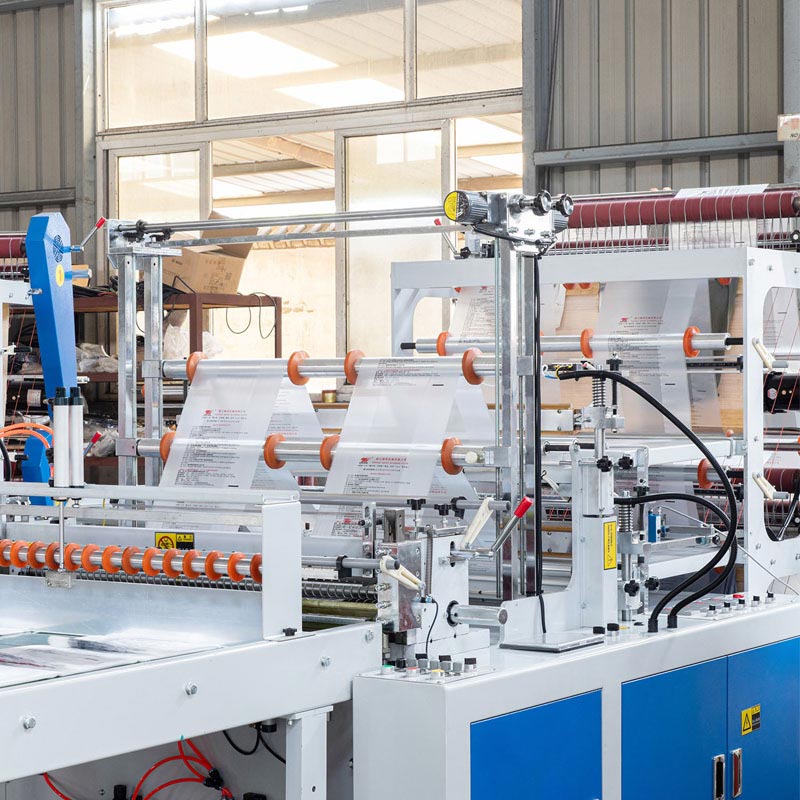

Efficient production

The photoelectric automatic control feeding device adopts advanced sensor technology to monitor the input status of materials in real time, and adjust the feeding rate through high-speed feedback mechanism to accurately control the feeding speed and quantity, ensuring the continuous supply and efficient utilization of materials in the production process, reducing labor costs, and improving production efficiency.

Multifunctionality

Suitable for materials such as HDPE , LDPE and PP, and for various types of bags such as vest bags and flat bags.

Precise control

Imported photoelectric tracking system ensures accurate and smooth sealing and cutting, and automatic shutdown for label loss.

Automated design

Stepper motor drag, automatic counting, adjustable stacking number, automatic whole book discharge.

product video

product video

Inquiry Now

Inquiry Now