Understanding the functionality and benefits of film blowing machine clarifies their impact on production efficiency. With features like automation, manufacturers can maintain consistent quality while reducing waste. The innovative production techniques being adopted, such as real-time monitoring systems, are crucial for enhancing material performance.

Key components driving efficiency include the extruder, die head, and air cooling systems, which collectively contribute to optimal film properties. Moreover, the real-world applications of these machines illustrate their versatility across industries. By continually refining their processes and technologies, manufacturers can achieve significant gains in productivity and product quality.

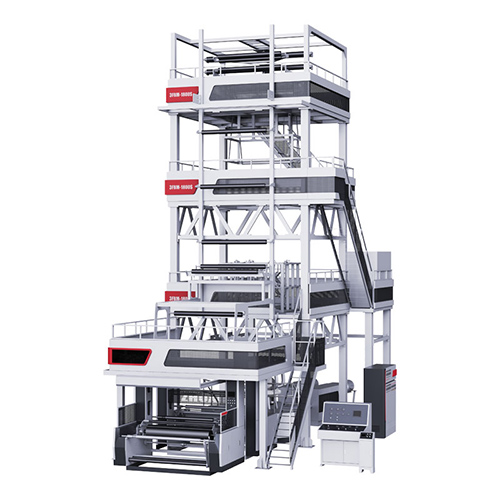

Understanding the Functionality and Benefits of Film Blowing Machine

Film blowing machine play a crucial role in the production of various plastic films, widely used in packaging and other applications. The benefits of using film blowing machine are substantial; they allow for precise control over the thickness and width of the film, contributing to consistent quality.

Additionally, modern film blowing technology incorporates advanced automation features. This not only enhances production efficiency but also reduces waste during manufacturing. As a result, operations can achieve higher output levels while maintaining quality standards.

Incorporating innovations such as multi-layer technology has further broadened the applications of blown films, enabling the production of complex structures that enhance barrier properties essential for food packaging or medical supplies.

Innovative Production Techniques in Film Blowing Technology

Recent advancements in film blowing technology have significantly improved production efficiency and material performance.

1.Automation Integration: A Film Blowing Machine uses automation to monitor and adjust speed, temperature, and pressure in real time, ensuring consistent quality and minimizing waste.

2.Advanced Die Design: Modern Film Blowing Machine employ advanced die designs that improve melt flow and enable the production of multi-layer films with different properties.

3.Hybrid Methods: Some Film Blowing Machine combine traditional blowing with co-extrusion processes, allowing for better material combinations and increased functionality.

As a result, these innovative approaches are setting new standards for productivity and sustainability in the film manufacturing industry.

Key Components Driving Efficiency in Film Blowing Machine

The efficiency of film blowing machine hinges on several critical components that work in concert to optimize production.

1.Extruder: A Film Blowing Machine uses an extruder to melt and mix the polymer, a process critical to output quality and speed.

2.Die Head: The Film Blowing Machine's die head shapes the molten polymer into a tube, ensuring uniform thickness and enhancing mechanical properties.

3.Air Cooling System: A Film Blowing Machine relies on a precise air cooling system to control the film's cooling rate, which determines its final properties.

4.Control Systems: An advanced Film Blowing Machine integrates control systems for real-time monitoring and adjustment, boosting reliability and efficiency.

Together, these components create a cohesive system that maximizes productivity while maintaining high-quality standards in film production.

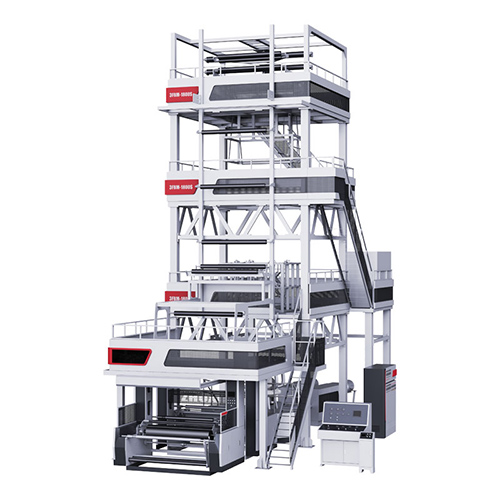

Real-World Applications: Optimizing Film Manufacturing Processes

Film blowing machine are integral to the efficiency and versatility of film production. In industries ranging from packaging to construction, these machines facilitate the creation of films that meet specific performance requirements.

1.Enhanced Packaging: A Film Blowing Machine produces films with superior barrier properties to protect against moisture and oxygen, extending product shelf life.

2.Automated Control: An advanced Film Blowing Machine allows for real-time monitoring and adjustment of parameters, ensuring consistent quality and reducing material waste.

3.Material Optimization: By fine-tuning raw material blends, a Film Blowing Machine can be optimized to produce film with specific features like clarity or strength.

Such innovations illustrate how the integration of modern technology in film blowing processes is driving substantial improvements in manufacturing efficiency and product quality across various fields.

Conclusion

The Film Blowing Machine is an essential tool in modern manufacturing, significantly enhancing production efficiency and film quality through advancements in automation and control technologies. It enables the precise production of innovative, high-performance films, such as those with superior barrier properties from multi-layer structures.

By leveraging these modern techniques and optimized processes, the Film Blowing Machine allows businesses to maintain competitiveness in a rapidly evolving market.

Act now!

Contact our team of expert consultants today for industry solutions and detailed product information!